Adelphi offers both a wide range of both stained and painted wood finishes and distressing options, and a large selection of modern engineered finishes: some that resemble wood and some that do not. This guide should help you to narrow down your choices.

Standard wood finishes

In selecting wood for your cabinetry, remember that trees are a product of nature and that no two grow identically. The grain, texture, and base color of the wood will vary. These variations should be viewed as a desired highlight; connoisseurs of fine wood furniture appreciate these differences, and we are sure that you will be delighted as well since your product will be entirely unique. Experienced dealers will point this out at the time of the sale and, by doing so, should help eliminate any unexpected problems.

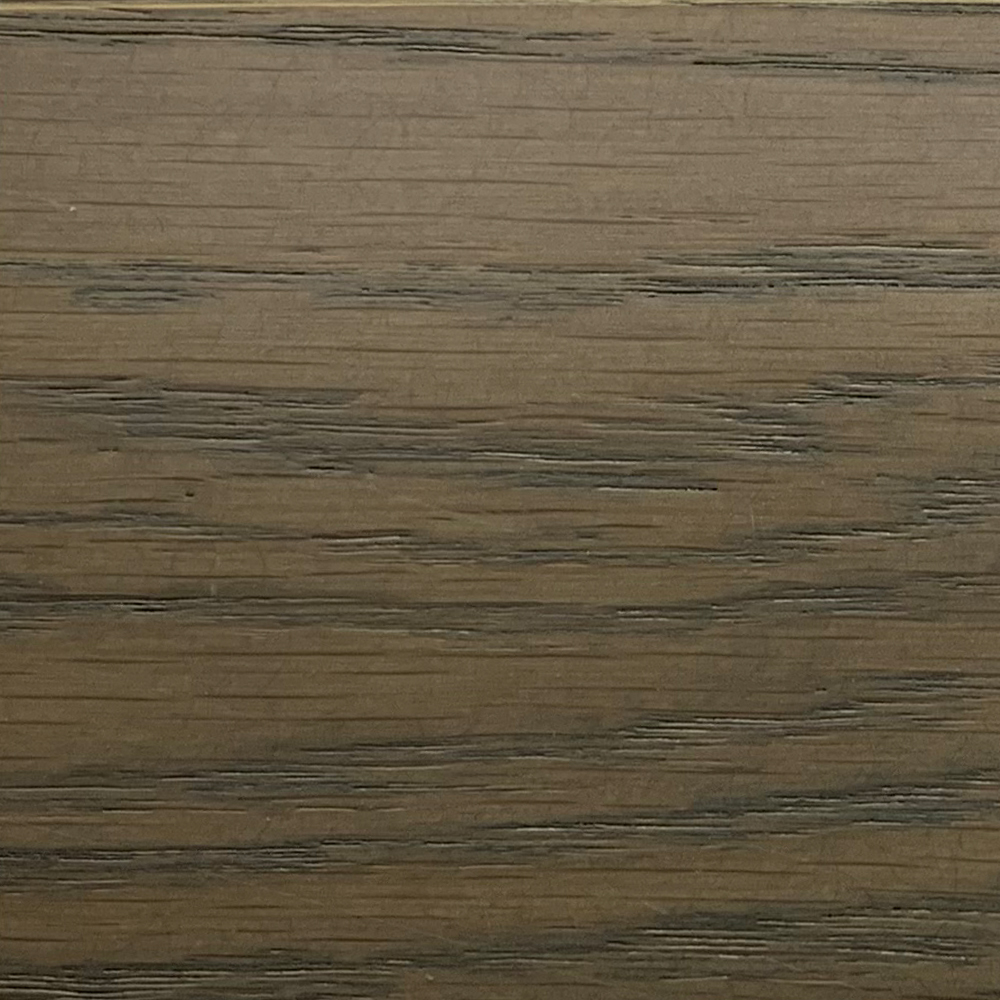

Oak wood

Types of finishes available in oak wood cabinets include hand-wiped stains, wired finishes, and specialty fashion colors.

Coloration of white oak will vary from light brown to a grayish tint in the heartwood. Two shades of ochre may appear in the sapwood. The wood rays are more pronounced and longer than in red oak. All white oak wood is heavy, very hard, and strong. Any knots will be small and well-scattered.

Birch wood

Types of finishes available in birch wood cabinets include hand-wiped stains and specialty fashion colors. This wood can vary from light brown tinged with either pinkish or grayish undertones, with a thin, nearly white sapwood. Birch is a close-grained wood with a distinct, but not prominent, pattern.

Cherry wood

Types of finishes available in cherry cabinets include hand-wiped stains and specialty fashion colors. Premium and rustic cherry woods are also available in some lines.

Most people visualize cherry wood with a reddish-brown color. This is indeed the tone seen in most cherry furniture. However, a fair amount of cherry also has a distinctively grayish cast, while other pieces have a light straw color. The freshly cut heartwood is usually light amber in tone, but will darken considerably with age and exposure to sunlight. Cherry sapwood is even lighter in color, from white to a light red-brown. Cherry wood often has black “pitch marks” which appear as small, dark lines. These are not considered defects, but are in fact inherent to the wood itself. Cherry is stiff, strong, and moderately hard.

Maple wood

Types of finishes available in maple cabinets include hand-wiped stains and specialty fashion colors. Adelphi uses only hard white maple. Some maple wood may also be used for paint-grade finishes (see “Full Cover” below).

White maple is a mildly grained hardwood that is predominantly blonde in color. It may have light and dark streaking through the grain, as well as spots of darker mineral coloration. Maple is tight-grained and moderately strong. Hard white maple is cleaner, whiter, and contains far less mineral coloration than soft white, used by some other manufacturers.

Walnut wood

Types of finishes available in walnut wood cabinets include hand-wiped stains, wired finishes, and specialty fashion colors.

Walnut varies from a light gray-brown to dark chocolate brown, sometimes even to a dark purplish shade. Grain patterns in walnut vary strongly from piece to piece and can be very plain or highly figured.

Alder wood

Types of finishes available in alder wood cabinets include hand-wiped stains and specialty fashion colors. A rustic variant, knotty alder, is also available.

A member of the birch family, alder is a moderately light-colored hardwood which is cream-colored when newly cut and turns a pink-orange shade while being worked. This “color bleeding” causes mature alder wood to be beautifully tinted and veined. Alder is much sought by furniture makers due to its distinctive character.

Knotty pine wood

Types of finishes available in knotty pine cabinets include hand-wiped stains and specialty fashion colors.

Knotty pine is a very soft wood with distinctive knots and graining. It tends to be a light yellow color that will vary to off-white at spots, while the knots are very dark brown at the center. Knotty pine is easily marred and dented; therefore, it is most commonly ordered with a distressing procedure applied. Some knots may be saw-cut but will always be stable.

Brier Select

Brier Select cabinetry uses a mix of white hardwoods, such as birch and maple, to achieve unique character with special consideration given to both price and quality. It offers a curated selection of best-selling doors and a stain selection that has been specifically targeted to show off the unique qualities of this line.

A limited selection of both hand-wiped stains and full-cover finishes are available in Brier Select.

Full cover finishes

“Full cover” means a “paint-style” finish. Adelphi Kitchens does not use enamel paint. Your cabinets are manufactured in a moisture-controlled environment where the moisture content of the selected hardwoods and veneers we use is kept to an accepted range for fine furniture construction. However, when cabinets leave the factory and go to another location where the humidity level is too high or the conditions are too dry, wood parts may expand and contract.

For painted cabinetry, Adelphi will select the material, which can include high-density fiberboard (HDF) or paint-grade maple. You can specify all-wood, hybrid, or all-HDF doors by noting this on your order when it is sent in.

Paint grade colors are available from our standard selection or with glazing or other top-coat options applied.

Engineered finishes

A variety of types of “manufactured” or “engineered” finishes are available, such as textured and untextured laminates, thermofoil, acrylics, and nanotechnology matte surfaces.

Strata

Strata doors are constructed of thermo-textured surface panels that undergo a process of thermally fusing decorative, high-resolution wood grain prints.

Made with sustainable materials, such as wood chips, fiber, and recycled woods, Strata has the right density to achieve these unique textures while remaining an environmentally friendly option.

SelecTexture

Built in the same way as Strata, the SelecTexture line is more subtly embossed and thus does not look or feel as “grainy”. These surfaces are only available as a part of our Brier Select line.

3D Laminate

Part of our Euro-Contemporary line, the 3DL program has a wide variety of matte colors, textures, wood grains, and gloss levels. Manufactured from PVC, these laminate membranes have consistent coloration, finish, and surface quality from edge to edge. Doors using 3D laminates are manufactured from engineered CARB II compliant board core with the membrane pressed to the exterior, giving a clean and contemporary final look. Each door comes with your choice of up to five edgebanding colors.

Level Acrylics & Nanotech

The other half of our Euro-Contemporary line, Level doors are flat laminated with a variety of edgebanding options. Advanced techniques allow for a high substrate-to-material bond strength, as well as higher resistance to heat and moisture. High-gloss acrylic components feature a colored layer of acrylonitrile butadiene styrene (ABS) that is permanently fused with a clear, high-gloss acrylic top layer. ABS is a high-quality, ecologically responsible thermoplastic. Other options include wired 2D PVC laminate and FENIX nanotechnology made with next-generation acrylic resin.

Tekton Laminate

Tekton laminate doors are made from slab HDF with high-pressure laminate applied to both sides. Door edges are banded with matching edgebanding or have the same matching material as the cabinet front. Tekton cabinets are a great choice for high-traffic or high-use areas, such as garages or laundries, or for light commercial applications.

Finish customization options

Sheen Top Coats

Our standard top coat for cabinetry is similar to a semi-gloss finish. It is applied over the top of any finish that is purchased by default to protect the stains and paints for a long, durable life of use.

Low-sheen and high-sheen top coats are available for looks that are more matte or more glossy. On the Brier Select line, the low sheen top coat is always standard rather than the standard sheen.

Finish Over-Coating

A range of treatments are available for finishes to enhance the look of a basic paint or stain. These options cannot be applied to engineered finishes.

Glazing

Standard glazes are wiped on over your chosen finish; they can be applied over stains or paints. These are wet glazes and are available in five colors: white, black, brown, mocha (a grayer brown), and champagne. Glaze will “hang up” in corners, on raised panels, and on non-straight edges and will gently lighten or darken the underlying finish coat.

Brush Streaking

Brush streaking is a secondary finishing treatment that is only usable with glaze also applied. In this process, the glaze is wiped with a brush after application, so the color of the glaze will be more prominent. In addition to the hang-up on corners and edges, the glaze will be visible “streaked” over most flat surfaces of the door. This is an attractive antiquing option that is more obvious than standard glaze.

Cerusing

Cerusing is a dry glaze process that can only be applied to open-grain woods. In Adelphi’s line, cerusing is applied to white oak only as a standard option. In cerusing, a white dry glaze is rubbed into the grain of the wood. This highlights the grain and adds multiple layers of visual interest to the final finished product.

Striping

Striping is a hand-painted process which adds a specified color to the edges and corners of the door panel, framing bead, and raise. It’s a very effective treatment and is used for some of our fashion colors. Available striping colors include white, black, brown, copper, and silver. At right: Dove with copper striping.

Fly Specking

To simulate fly specking, paint is splattered on the cabinet surface with a small brush. Generally, fly specking is done in black or white. Stained or painted finishes can benefit from fly specking treatment. At right: Snowcap with black fly specking.

Distressing

Eased Edges

The eased edge process is a gentle softening on the finished edges of doors. It is not as visually assertive as the French-cut or sanding process, although it may be combined with either of these to make the effect more visible. Edges are eased prior to finishing, so the door will appear to have mild imperfections beneath the paint or stain.

French cutting & sand through

Using a small tool like a rasp, the French cutting process exposes an undercoat or the natural wood beneath a full-cover finish. An example of a finish that uses French cutting by default is Farmhouse Blue. If you would like to see a stain undercoat in the cut areas, you will need to supply a stain color as well as your full-cover paint choice. If not specified, the French cut will show the natural wood color instead.

In the Sand Through process, edges and corners are heavily sanded to reveal the natural wood beneath. This process can be applied to either full-cover or stained finishes. Sand Through will remove much more material than Eased Edges or French Cutting and can be combined with either; it will generate the most irregular results out of these three choices.

Dimensional Distress

Dimensional distress does exactly what the name implies: distresses the cabinet and door by adding dimension. This is accomplished by striking the wood with blunted stones in order to dent it. This type of distressing will vary greatly from item to item.

Heavy Distress

For even more distressed looks, the Heavy Distress process consists of a wide range of distressing techniques, some of which can be used individually but which are shown here together for context, since they are often combined.

Sanding

Heavy distress sanding is simply a heavier version of the “Sand Through” shown above.

Awl holes

A sharp, pointed awl is used to drive holes into the wood of the door, the frame, or the cabinet side. An average cabinet door may receive 10–15 awl holes, while larger doors may have 20 to 25. Usually they are grouped together on the cabinet; however, they can be spread out as well. Awl holes are irregular and will not be “perfect”.

Gouges

Gouges are sliced into the door, similar to the awl holes, but long and thin. An average door may have around six gouges; smaller doors can have less and larger doors more.

Cracks

Cracks are broken into the door and frame, with 3 to 5-inch wire brushing around the cracks to simulate distress to the wood. Standard doors will have two randomly-placed cracks, while larger doors may have three to four.

Dimensional distress

See above for details on dimensional distress.